- HOME >

- PRODUCTS & SERVICES >

- LASER WELDING EQUIPMENT

LASER WELDING EQUIPMENT

PLW Series

Features

- ・Powerful laser welding equipment with high-speed, high-quality, high-stability mounted pulse YAG laser oscillator

- ・Lineup of 8 types, 30W–600W. Adaptable to a wide range of welding, from fine precision welding to automobile parts welding.

- ・Minimum beam diameter φ0.2mm– * Contact us for inquiries about smaller diameters

- ・Ease of switching between manual operation and automated operation allows one unit to cover prototyping, development, and mass production

- ・Workpiece is fixed in place at the processing stage and the laser emitting unit scans in the X, Y, and Z axes, for optimal processing of difficult-to-handle long workpiece or heavy workpiece

- ・Includes safety cover as standard equipment. * Can be adapted to Class 1 specification

- ・Adaptable to custom designs (inlining, fiber laser/semiconductor laser mounting, etc.)

Applications

Welding of electronic components, electrical components, machinery components, components for medical use, optical components, precision sheet metal

Welding of battery tabs, wire materials, terminals, copper wire for motor coils, etc.

Metal welding, alloy welding, lap welding, butt welding

Examples of processing

Medical-use metal wire tip sphere

Wire φ0.2mm, sphere diameter φ0.35mm

Medical-use metal wire tip hemisphere

Wire φ0.2mm

SUS pipe end seal welding

Wire φ0.2mm

Cu plate butt welding

Plate 1.0mm

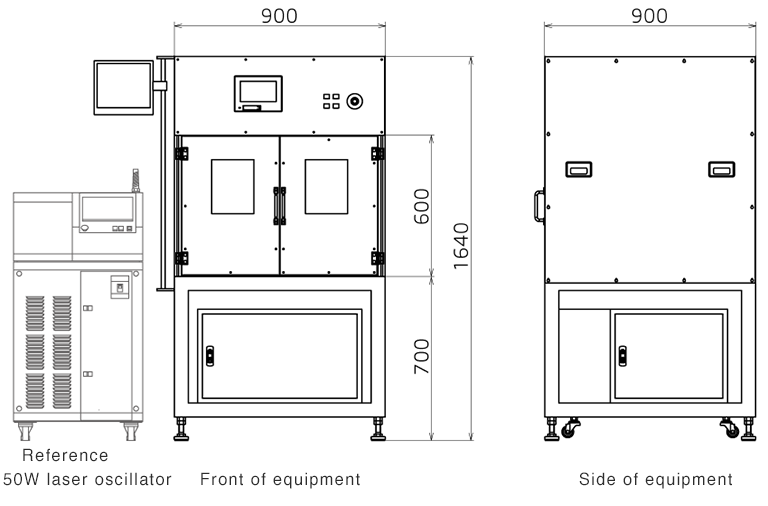

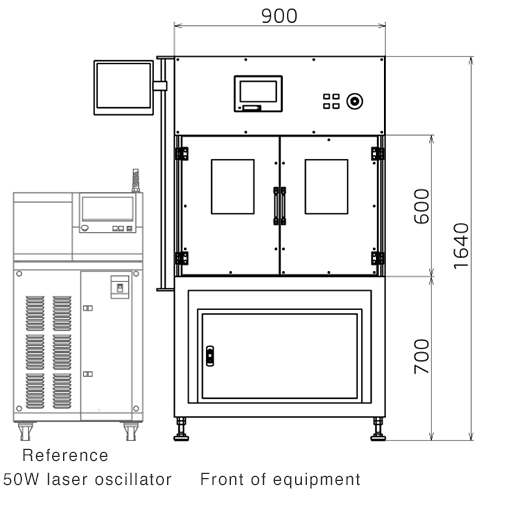

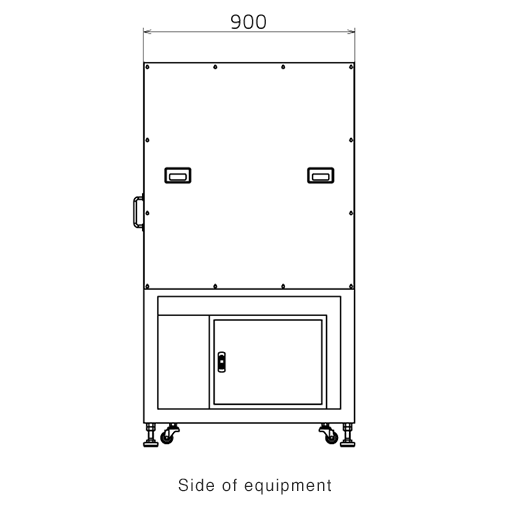

External dimensions of equipment

Equipment specifications

| Laser oscillator | Type of laser | YAG laser |

|---|---|---|

| Wavelength | 1064nm | |

| Output | Selection from 8 types, 30W–600W | |

| Peak power | 3kW–10kW (depending on laser used) | |

| Maximum output energy | 30J–100J/P @10ms | |

| Number of pulses | 0.3ms–100ms (depending on laser used) | |

| Maximum repetition frequency | 30pps–500pps (depending on laser used) | |

| Processing actions | Effective scope of processing | 300mm × 300mm |

| Laser irradiation method | Laser irradiation unit travel + laser irradiation synchronization | |

| Precision of repeated positioning | (X,Y,Z) ≦ ±0.025mm | |

| Positioning resolution | (X,Y,Z) ≦ 0.01mm | |

| Maximum speed of travel | (X,Y) ≧ 100mm/sec (Z) ≧ 10mm/sec | |

| Power required | Power source | Three-phase 200/220V ±10% 50/60Hz |

| Electric power used | 25A–70A (depending on laser used) |

・Laser oscillator

Wavelength: 1064nm

Output: Selection from 8 types, 30W–600W

Peak power: 3kW–10kW (depending on laser used)

Maximum output energy: 30J–100J/P @10ms

Number of pulses: 0.3ms–100ms (depending on laser used)

Maximum repetition frequency: 30pps–500pps (depending on laser used)

・Processing actions

Laser irradiation method: Laser irradiation unit travel + laser irradiation synchronization

Precision of repeated positioning: (X,Y,Z) ≦ ±0.025mm

Positioning resolution: (X,Y,Z) ≦ 0.01mm

Maximum speed of travel: (X,Y) ≧ 100mm/sec (Z) ≧ 10mm/sec

・Power required

Electric power used: 25A–70A (depending on laser used)

Demo equipment viewing

Viewing demo equipment is possible.

To request viewing, inquire through the website with the requested date, time, and number of people.

Location of demo equipment: FURUKAWA BUSSAN CO., LTD. YOKOHAMA LAB. (Iida Bldg. 1F, No.50, Tobecho 3-chome, Nishi-ku, Yokohama City, Kanagawa, Japan)