- HOME >

- PRODUCTS & SERVICES >

- LASER HARNESS PROCESSING MACHINES

FBC LASER HARNESS PROCESSING MACHINES

Product Lineup

We also handle pre and post process equipment. Please contact us for more information.

CONTACTFeatures of the FBC Laser Harness Processing Machine

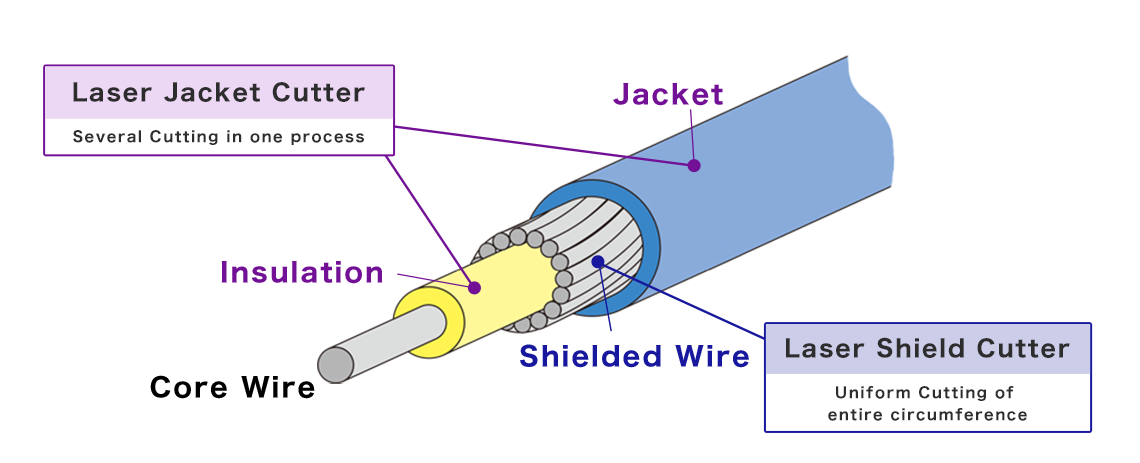

1 Since this is non-contact processing, it is not restricted by the shape of the workpiece, and no damage is caused to the metal conductor.

2 It is also compatible with soft insulation such as foam.

3 Because there is almost no effect on the processing accuracy by wearing of components as in the case of a blade, a constant processing accuracy can be maintained over a long period of time.

4 The insulation on multiple multi-core cables can be processed simultaneously.

5 Multiple cables can be arranged on a jig and processed in a batch.

6 Braided shield wires too can be processed without damaging the insulator pre-soledring is not required.

7 It is also widely used in semiconductor measuring equipment harness with strict electrical characteristics requirements.

Others

・ The CO2 laser cuts only the insulation and does not damage the shield wire and core wire.

・ Being a dedicated cable stripping machine, the operator need not perform cumbersome tasks such as reversing the workpiece.

Processing Examples

[Micro Wire Multi-core Laminate] - Processing Example of Three-stage Stripping of Coaxial Wires -

<Cable specifications>AWG44 coaxial wire x 32-core laminate

<Processing specifications>

Three-stage stripping on both ends, dimensional tolerance ±0.05 mm or less

<Processing takt>

6 laminates (both ends) in approx. 55 seconds

* Depends on the cable and processing accuracy

<Devices used>

Laser jacket cutter, laser shield cutter

jacket stripper, shield stripper, tip cutting tool

[AWG40 Braided Coaxial Wire] - Processing Example of Three-stage Stripping of Coaxial Wires -

<Cable specifications>AWG40 coaxial wire

<Processing specifications>

Three-stage stripping on both ends, dimensional tolerance ±0.05 mm or less

<Processing takt>

280 wires (both ends) in approx. 70 seconds

* Depends on the cable and processing accuracy

<Devices used>

Laser jacket cutter, laser shield cutter

jacket stripper, shield stripper, tip cutting tool

[AWG36 Braided Coaxial Wire] - Processing Example of Three-stage Stripping of Coaxial Wires -

<Cable specifications>AWG36 coaxial wire

<Processing specifications>

Three-stage stripping on both ends, dimensional tolerance ±0.05 mm or less

<Processing takt>

180 wires (both ends) in approx. 75 seconds

* Depends on the cable and processing accuracy

<Devices used>

Laser jacket cutter, laser shield cutter

jacket stripper, shield stripper, tip cutting tool

[Coating Wire] - Processing Example of Laser Burn-off of Coating -

<Cable specifications>Coil wire (outer diameter Φ1.9 mm), ETFE coating 200μm

<Processing specifications>

Laser burn-off (laser burn-off range: 2 mm), dimensional tolerance ±0.05 mm or less

<Processing takt>

110 wires (single end) in approx. 35 seconds

* Depends on the cable and processing accuracy

<Devices used>

Laser jacket cutter

Sample Test

Please ask us to process test sample.

| Cutting of insulation | Laser Jacket Cutter JC-H100 | |

|---|---|---|

| Cutting of shield wire | Laser Shield Cutter SC-H100 | |

| Stripping of insulation | Jacket Stripper JS-AC01 | |

| Stripping of shield wire | Shield Stripper SS-BV | |

| Cutting of insulation | Insulated cable with an outer diameter of φ2mm or less (up to φ8 mm depending on the material) | |

| Cutting of shield wire | AWG50 to 26 coaxial cable (up to φ3 to 4 mm with pre-soldering) * Pre-soldering is not required for AWG36 or lower braided wires (varies depending on conditions) | |

・Cutting of insulation

・Cutting of shield wire

・Stripping of insulation

・Stripping of shield wire

・Cutting of insulation

(up to φ8 mm depending on the material)

・Cutting of shield wire

* Pre-soldering is not required for AWG36 or lower braided wires (varies depending on conditions)

* The above data is for reference. It may vary depending on the material, wire configuration, and other conditions.

Demo equipment viewing

Viewing demo equipment is possible.

To request viewing, inquire through the website with the requested date, time, and number of people.

Location of demo equipment: FURUKAWA BUSSAN CO., LTD. YOKOHAMA LAB. (Iida Bldg. 1F, No.50, Tobecho 3-chome, Nishi-ku, Yokohama City, Kanagawa, Japan)