- HOME >

- PRODUCTS & SERVICES >

- LASER HARNESS PROCESSING MACHINES >

- Laser Shield Cutter

Laser Shield Cutter

LASER HARNESS PROCESSING MACHINES

Laser Shield Cutter

(SC Series)

Shield wires and metal tapes can be processed uniformly across the entire circumference

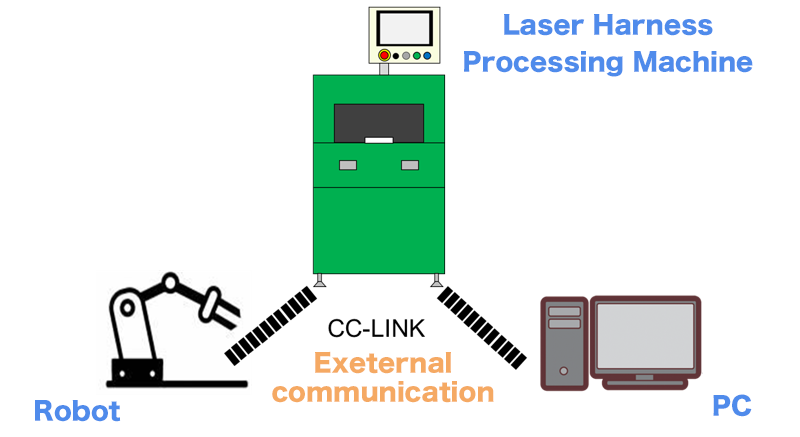

Equipped with external communication function by CC-LINK

Features of YVO4 Laser Processing

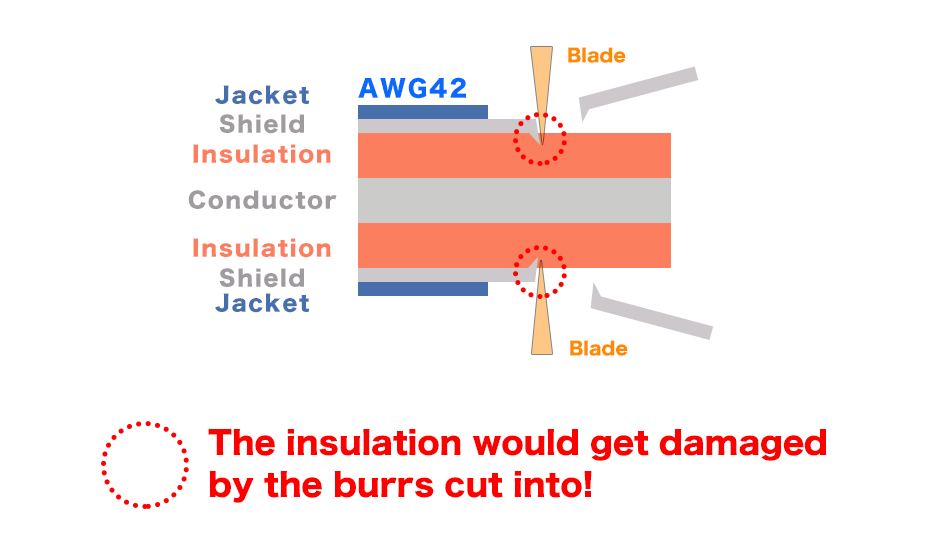

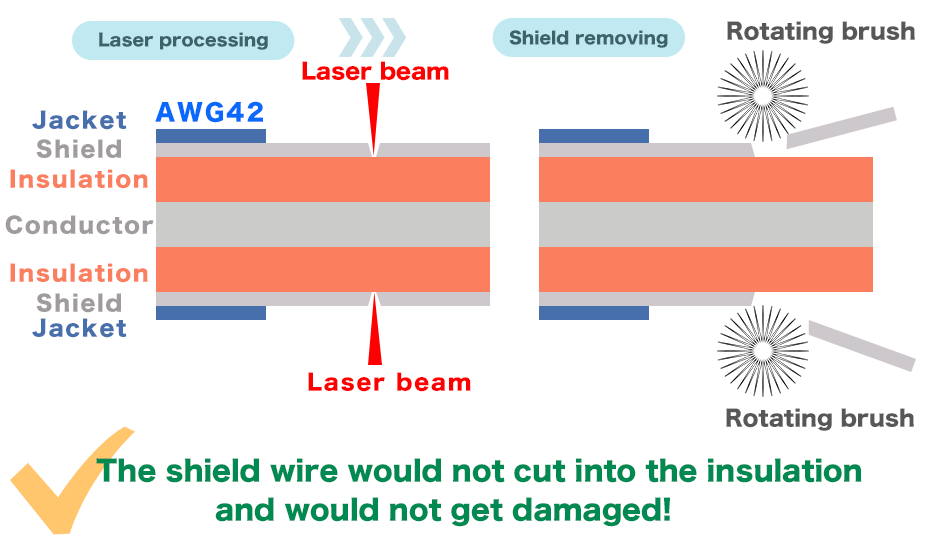

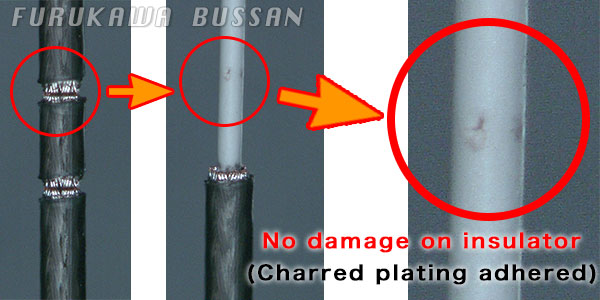

1The shield wire does not cut into the insulation.

In the case of a mechanical stripper using a blade, cutting is performed while applying pressure on the shield wire from outside, and therefore, the shield wire cuts into the insulator.This may affect the characteristics of the cable. Shield cutting by the laser is non-contact nature. Since the depth of cut can be stably controlled, it is possible to cut up to half of the shield wire and remove the shield with a rotating brush type shield stripper (shield stripper SS-BV) without affecting the insulation.

< Image of mechanical cut >

< Image of YVO4 laser cut >

2Reduces thermal damage to the insulation

Because of its low peak power and high repetition oscillation frequency characteristics, the YVO4 laser can reduce the amount of heat generated during processing the shield cable and reduce thermal damage to the insulation under the shield cable.

3No change in processing accuracy caused by component consumption.

Since there is no effect on processing accuracy due to wear of parts like blades, a constant processing quality and processing accuracy can be maintained for a long period of time.

Dedicated Cable Stripping Machine

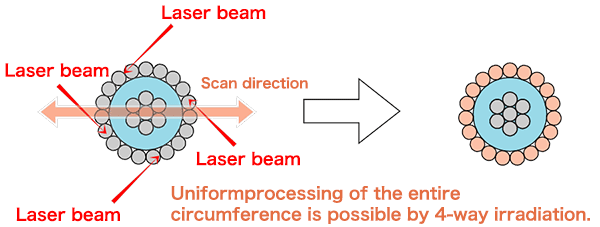

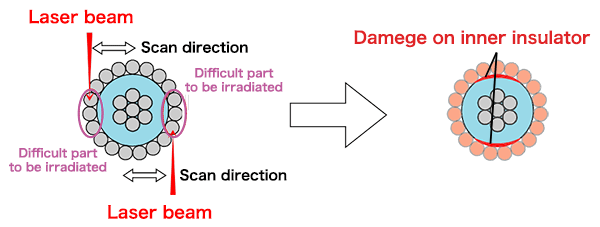

1No uncut portions or damage on the insulation

In the case of a 1-way irradiation device using a laser marker, or any other 2-way irradiation laser processing machine, there are portions that are not irradiated sufficiently by the laser, and also portions that are strongly irradiated.

In this machine, the laser is irradiated from four inclined directions based on a unique device mechanism. The entire circumference of the shield is cut uniformly.

< FBC Laser Shield Cutter >

< Laser marker and other general laser processing machines >

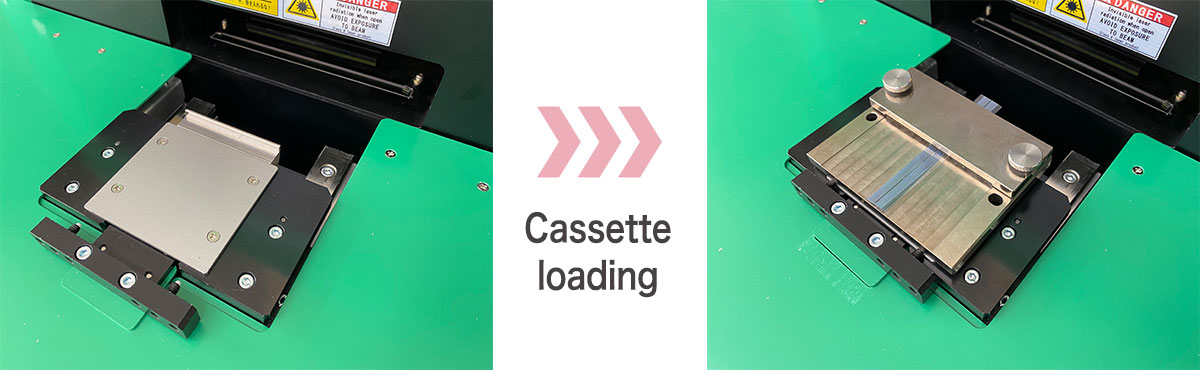

2A wide range of processing can be performed through a simple operation.

The simple operation involves only setting the workpiece and pressing the start button.

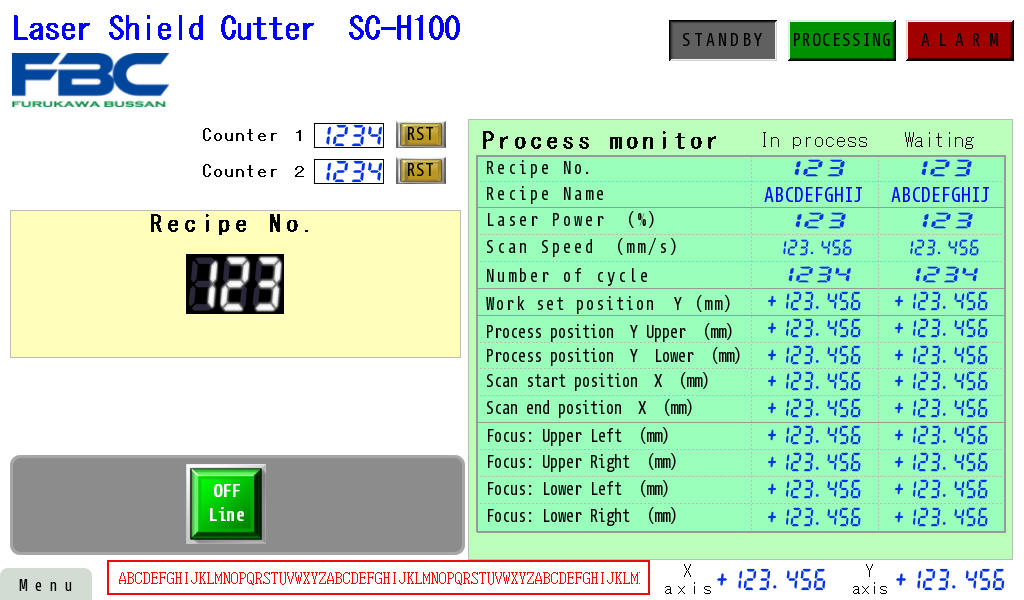

By combining together the "Laser processing conditions" and "Processing position conditions", changes in processing conditions by process and by product, and continuous processing of several locations can be performed through a simple operation of pressing the recipe selection button.

3Micro-processing and high-accuracy processing are realized

Through optimization of the optical design, beam-shaped laser irradiation that is suitable for shield cutting is performed, and this enables high-accuracy processing and micro-processing having very less heat damage on the circumference.

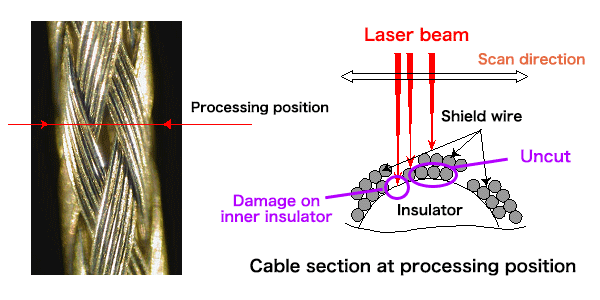

4Even micro braided wires do not require pre-soldering

A braided shield wire includes portions with double-wire thickness and portions with gaps as shown below. If the laser is irradiated, the shield wire that forms the inner layer in the double-wire portions remains uncut, and at the portions constituting the gaps, the laser permeates up to the inner insulator thus causing damage. Therefore, the extra labor of performing shield cutting after "pre-soldering" is required.

< Image of laser irradiation on braided wire >

< Processing involving pre-soldering on braided wire >

AWG26 braided coaxial wire

Since the 4-way laser irradiation enables uniform processing of the entire circumference by minimum laser irradiation, braided shield wires can be processed without leaving large scratches on the insulator even when pre-soldering is not performed.

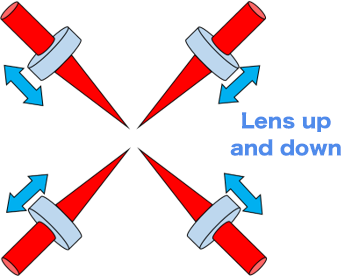

5Numerical control of focus position adjustment

4-way irradiation focus position adjustment

6Corresponds to automation line(external communication function added)

Customer Support

We support fast operation after installation of the machine

・ The processing test before shipment is implemented using the customer's workpiece. The processing test data is submitted to the customer.

・ During installation adjustment, the processing conditions are verified through customer's workpiece, and the processing position is set.

We support changes in cable specifications and setting processing conditions for new products

・Accoring to change of cable specifications, we perform the processing test for new products on our demonstration machine even after customer have purchased the machine. The processing recipe, etc. will be reported to customer.

・ We also offer development support for jigs and tools to be used and also the handling methods by exchanging information with customers.

Laser Shield Cutter Main Specifications

| Item | SC-H100 | SC-10FS | SC-10FL | |

|---|---|---|---|---|

| Laser oscillator | Type | 10W YVO4 Laser | ||

| Wavelength | 1064nm | |||

| Output power | 10W at 30kHz (Maximum average output) | |||

| Power stability | ±2% or less | |||

| Beam sizes | 60µm or less(Focusing Diameter) | |||

| Pulse range | Less than 40ns at 30kHz (Theoretical focusing diameter) | |||

| Pulse frequency | 20kHz ~ 100kHz | |||

| Head scanning | Effective processing range | 100mm | - | - |

| Maximum scanning speed | 300mm/s | - | - | |

| Processing position setting stroke | 50mm (Electric) | - | - | |

| Stage scanning | Effective processing length | - | 85mm | 300mm |

| Maximum scanning speed | - | (Y) 300mm/s | (Y) 300mm/s | |

| Processing position setting stroke | - | 15mm (Manual) | ||

| Optical unit | Focus adjustment mechanism | Electric(4 way) | Manual(Upper and lower 2 way) | Manual(Upper and lower 2 way) |

| Stage accuracy stage resolution | Processing position accuracy | Less than 0.05mm | ||

| Resolution | 0.01mm | |||

| Utility | Power supply | Single phase 50/60Hz 100~230V (1kVA) |

Single phase 50/60Hz 100~230V (800VA) |

|

| Air supply | 0.4Mpa or above | |||

| Exhaust air | 3.5㎥/min or above (Dia. 50mm Exhaust port) | |||

| Processing range(Target) | φ2mm~ AWG52 coaxial cable ※Pre-soldering required for braided wire larger than dia. 1 mm |

|||

| Exeternal communication | Only for SC-H100 | FBC standard external communication by CC-Link | ||

SC-H100

・Laser oscillator

Wavelength: 1064nm

Output power: 10W at 30kHz (Maximum average output)

Power stability: ±2% or less

Beam sizes: 60µm or less (Focusing Diameter)

Pulse range: Less than 40ns at 30kHz (Theoretical focusing diameter)

Pulse frequency: 20kHz ~ 100kHz

・Head scanning

Maximum scanning speed: 300mm/s

Processing position setting stroke: 50mm (Electric)

・Optical unit Focus adjustment mechanism

・Stage accuracy stage resolution

Resolution: 0.01mm

・Utility

Air supply: 0.4Mpa or above

Exhaust air: 3.5㎥/min or above (Dia. 50mm Exhaust port)

・Processing range(Target)

・Exeternal communication

SC-10FS

・Laser oscillator

Wavelength: 1064nm

Output power: 10W at 30kHz (Maximum average output)

Power stability: ±2% or less

Beam sizes: 60µm or less (Focusing Diameter)

Pulse range: Less than 40ns at 30kHz (Theoretical focusing diameter)

Pulse frequency: 20kHz ~ 100kHz

・Stage scanning

Maximum scanning speed: (Y) 300mm/s

Processing position setting stroke: 15mm (Manual)

・Optical unit Focus adjustment mechanism

・Stage accuracy stage resolution

Resolution: 0.01mm

・Utility

Air supply: 0.4Mpa or above

Exhaust air: 3.5㎥/min or above (Dia. 50mm Exhaust port)

・Processing range(Target)

SC-10FL

・Laser oscillator

Wavelength: 1064nm

Output power: 10W at 30kHz (Maximum average output)

Power stability: ±2% or less

Beam sizes: 60µm or less (Focusing Diameter)

Pulse range: Less than 40ns at 30kHz (Theoretical focusing diameter)

Pulse frequency: 20kHz ~ 100kHz

・Stage scanning

Maximum scanning speed: (Y) 300mm/s

Processing position setting stroke: 15mm (Manual)

・Optical unit Focus adjustment mechanism

・Stage accuracy stage resolution

Resolution: 0.01mm

・Utility

Air supply: 0.4Mpa or above

Exhaust air: 3.5㎥/min or above (Dia. 50mm Exhaust port)

・Processing range(Target)

Demo equipment viewing

Viewing demo equipment is possible.

To request viewing, inquire through the website with the requested date, time, and number of people.

Location of demo equipment: FURUKAWA BUSSAN CO., LTD. YOKOHAMA LAB. (Iida Bldg. 1F, No.50, Tobecho 3-chome, Nishi-ku, Yokohama City, Kanagawa, Japan)

The FBC Laser Harness Processing Machine Product Lineup

We also handle pre and post process equipment. Please contact us for more information.